VOCKE Refrigeration Equipment

Refrigeration compressor supplier and cold storage engineering design solution provider

We are a refrigeration compressor manufacturer integrating design, manufacturing, sales, engineering design and installation

26 years of innovative development

Start

Has won many honors

Patent

Be brave to innovate, compound talents

Employee

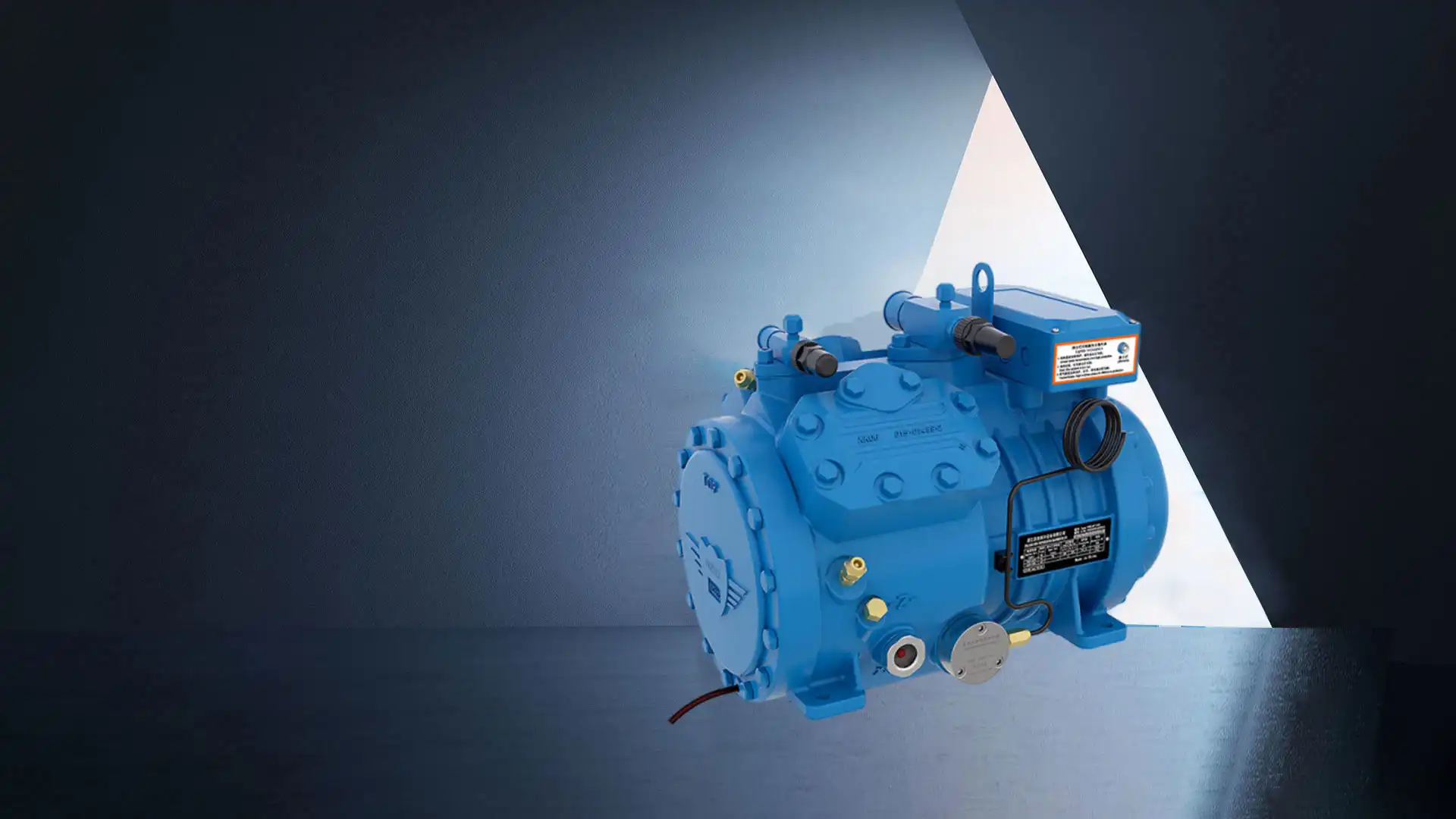

Featured Products

Product Advantages

We have developed a series of refrigeration compressors with low noise, low vibration, high energy efficiency ratio and large cooling capacity. Ensure the reliability and durability of the compressor, even in extreme operating conditions, the performance is still excellent. Superb compressor technology is reflected in high efficiency, low energy consumption, easy maintenance, high reliability, running comfort.

Learn more>

·Cylinder Honing System·

After honing, the cylinder wall

roughness reaches 0.4μm with a

cylindricity of 5μm. The cylinder

surface forms an angled cross-hatch

pattern, which helps prevent oil film

detachment, enhances cylinder

sealing and lubrication efficiency,

and reduces oil discharge.

·Coordinate Measuring Machine·

The motor cavity, bearing bore, and end

cover cavity of the compressor body, The

coaxiality of the three bores, The

perpendicularity and positionof the crankshaft

relative to the connecting rod and cylinder,

The cylindricity of the cylinder and the

accuracy of the cylinder stroke, The flatness

of the cylinder surface

·Disc Vlave Plate·

The disc valve plate utilizes annular valve

strips and a valve seat, complemented by

a uniform and rational gas flow path

design. This effectively mitigates valve

strip breakage caused by liquid slugging,

a benefit that is particularly pronounced

in low-temperature system operation.

·Electronic Integrated Protection Module·

Models in the Small Fourth and Medium

Fourth series are equipped with a standard

electronic oil level controller. This ensures

the compressor oil level is maintained

within a safe range. If the oil level drops

below the preset safety limit, the device

will immediately trigger a compressor

shutdown and activate a flashing fault

indicator.

Blogs

CERTIFICATION